Carbon Steel Socket Head Cap Screws

Carbon steel Socket Head Cap Screws have higher tensile strength and a smaller surface area required for countersunk head screws.

Send InquiryFeatures

Carbon Steel Socket Head Cap Screws: Introduction

Carbon steel socket head cap screws are one of the most widely used types of fasteners in the world. These screws have been designed to meet the needs of demanding applications that require high levels of strength and durability. They are made using high-quality carbon steel, which makes them corrosion-resistant and long-lasting.

These screws have a socket head cap, which is where the name socket head cap screw comes from. They have an allen key or hexagonal socket, which allows them to be easily inserted and tightened using a socket wrench. This makes them the perfect choice for applications where a fastener needs to be frequently adjusted or tightened.

The carbon steel socket head cap screws are available in a range of sizes and thread pitches, allowing them to be used in a variety of applications. They can be used for general-purpose fastening, for high-pressure applications such as oil and gas pipelines, or in automotive and aerospace industries.

Features and Benefits of Carbon Steel Socket Head Cap Screws

One of the key features of carbon steel socket head cap screws is their high strength. They are made from steel, which has a high tensile strength and can withstand high levels of stress without breaking or deforming. This makes them ideal for applications where a lot of force is applied to the fastener.

Another benefit of carbon steel socket head cap screws is their resistance to corrosion. They are coated with a layer of zinc, which protects them from rust and corrosion, even in harsh environmental conditions. This makes them suitable for use in outdoor applications, such as construction sites and mining operations.

Moreover, the socket head cap design of these screws allows for a high degree of precision and control when tightening. This makes them ideal for use in applications where tight tolerances or precise torque specifications are required.

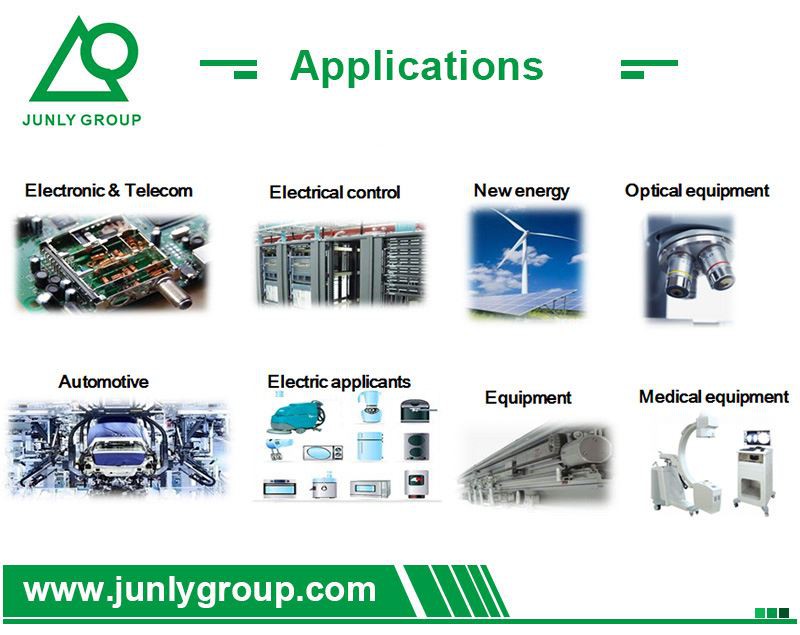

Applications of Carbon Steel Socket Head Cap Screws

Carbon steel socket head cap screws are widely used in a diverse range of applications due to their strength, durability, and resistance to corrosion. They can be used in construction, automotive, oil and gas, mining, and aerospace industries, among others.

One common application of carbon steel socket head cap screws is in the assembly of machinery and equipment. They are used to fasten components such as gears, rods, and pulleys, among others. In the automotive industry, they are used to secure engine parts, suspension components, and brake systems.

Carbon steel socket head cap screws are also commonly used in the manufacturing of electronics and instruments. The precision of their threading makes them ideal for use in these applications, where accurate alignment and fastening are critical.

Conclusion

Carbon steel socket head cap screws are a versatile and reliable type of fastener that is widely used in a variety of applications. Their high strength, durability, and resistance to corrosion make them an ideal choice for applications that require high levels of performance and reliability. They are easy to install and tighten, and their precision threading allows for a high degree of control and accuracy. Overall, carbon steel socket head cap screws have become an industry standard in a wide range of industries, from manufacturing to construction, due to their extensive advantages.

Introduction

Carbon Steel Socket Head Cap Screws have higher tensile strength, becoming the ideal choose for precision machinery processing. They are small, so they will not appear obtrusive when used on the surface of items, that is to say, they are suitable for processing items which have requirements on appearance. They are available in a variety of head shapes, like button head, pan head, CSK head, etc. An appropriately sized Allen key must be used when assembling and disassembling the socket head cap screws. They are generally used in the processing of various machine tools and accessories, structural steel, metal structures, oil and gas, towers and rods, machinery, automobiles, home decoration, etc.

Advantages

1. Carbon Steel Socket Head Cap Screws can withstand larger loads. They have six force-bearing surfaces, which are more resistant to screwing than flat-blade screws and cross-shaped screws.

2. They can be countersunk in use, that is, the whole nut is sunk into the inside of the workpiece, which can keep the surface of the workpiece smooth and beautiful.

3. They are easy to install. They are suitable for many decoration occasions, especially for narrow occasions.

4. They are not easy to disassemble. A special wrench must be used to remove them.

Specifications

● Type: Bolts/ Screws

● Size: M3-M14; #0-#12;1/4-9/16;ST2.9-ST9.5; Special size can be enquired and supported

● System of Measurement: Metric/Inch

● Product Executive Standards: ANSI, DIN, ISO, GB; or according to customer's drawing

● Material: Low carbon steel / medium carbon steel / alloy steel

● Grade: Quenching and tempering heat treatment—4.6/4.8/5.6/5.8/6.8/8.8/9.8/10.9/12.9/Grade 5/ Grade 8

Case harden-- Surface hardness min450HV

Core hardness 270~390HV/290~370HV

● Support non-standard customization

Hot Tags: carbon steel socket head cap screws, China carbon steel socket head cap screws manufacturers, suppliers, factory, 14mm fine thread bolt, m6 9mm screw, m8 by 1 25 bolt, cotter pin set, bolt with pin hole, bolts for sistering joists

You Might Also Like

Hex Socket Button Head Screws

Learn More

Double End Stud Bolt

Learn More

Stainless Steel 304 Hex Bolt

Learn More

Stainless Steel Hex Bolts

Learn More

Carbon Steel Hex Bolts

Learn More

Carbon Steel Nut

Learn More

Send Inquiry

Copyright © SIP Junly Industrial Precision Co., Ltd. All Rights Reserved.