SEMS Screws

SEMS Screws have a wide range of uses. Using the best characteristics of additional washers and screws, they are combined into a powerful washer.

Send InquiryFeatures

SEMS Screws are an essential component in the manufacturing process, which are used for fastening applications. These screws, also commonly known as combination screws, have a unique design that combines two components (such as a screw and a washer or a screw and a flat piece of metal) into one cohesive unit.

At our manufacturing facility in China, we specialize in producing high-quality SEMS Screws to meet the needs of merchants and manufacturers worldwide. Our SEMS Screws are highly regarded for their durability, reliability, and unmatched performance in a variety of applications.

There are several key aspects that set our SEMS Screws apart from the competition, including:

1. High-Quality Materials: We use only the finest materials in the manufacturing of our SEMS Screws, including top-grade metals such as stainless steel, brass, and aluminum, as well as high-performance coatings to enhance durability and resist corrosion.

2. Precise Engineering: Our SEMS Screws are designed using advanced CAD software and produced using state-of-the-art CNC machinery to ensure precision and accuracy in every screw we produce.

3. Customization: We understand that every manufacturing process is unique, which is why we offer the option to customize SEMS Screws to meet the specific needs of our clients. Whether you need a custom size, shape, or material, we can work with you to create the perfect SEMS Screw for your application.

4. Competitive Pricing: As a leading manufacturer of SEMS Screws in China, we are able to offer highly competitive pricing without compromising on quality or performance.

In addition to these key aspects, there are several specific applications where our SEMS Screws are particularly well-suited. These include:

- Automotive Manufacturing: SEMS Screws are commonly used in automotive manufacturing for their reliability and durability in harsh environments.

- Electronics and Appliances: The compact size and customizable design of SEMS Screws make them ideal for use in small electronics and appliances.

- Aerospace and Defense: SEMS Screws are frequently used in the aerospace and defense industries for their precision and reliability in critical applications.

- Medical Devices: SEMS Screws are often used in medical device manufacturing for their corrosion resistance and biocompatibility.

Overall, our SEMS Screws offer a reliable and cost-effective solution for manufacturers and merchants in a wide range of industries. With our commitment to quality, customization, and competitive pricing, we are confident that our SEMS Screws will exceed your expectations and meet the needs of your specific application.

Introduction

SEMS Screws are combinations of a screw, a spring washer and a flat washer, which are fastened together by rubbing the teeth. There are also many types, including split type, gasket type, etc. These screws with corresponding washers are very convenient to use, and do not need to manually allocate spring flat washers, which saves time, can make the production line easy to operate and improve work efficiency.

The stability of SEMS Screws is stronger than that of ordinary screws, so they are often used on many occasions. In addition, they are also very easy to install, making them one of the most cost-effective options for large-scale applications. Mainly used in railway and highway bridges, boiler steel structures, industrial plants, high-rise civil buildings, tower and mast structures, hoisting machinery and their steel structures where friction-type high-strength bolts and screws are required.

Product Details

● Product Type: Screws/Bolts

● Product Name: SEMS Screws

● Size: M3-M14; #0-#12;1/4-9/16;ST2.9-ST9.5; Special size can be enquired and supported

● Product Executive Standards: ANSI, DIN, ISO, GB;or Per customer’s drawing

● System of Measurement: Metric/Inch

● Head type: Button Head; Pan Head; CSK Head; Truss Head; Round Head; Cheese Head;Hexagon head; etc.

● Material: Low carbon steel / medium carbon steel / alloy steel

● Grade: Quenching and tempering heat treatment--4.6/4.8/5.6/5.8/6.8/8.8/9.8/10.9/12.9/Grade 5/ Grade 8;

Case harden-- Surface hardness min450HV

core hardness 270 ~ 390HV/290~370HV

● Support non-standard customization

● Country of Origin: China

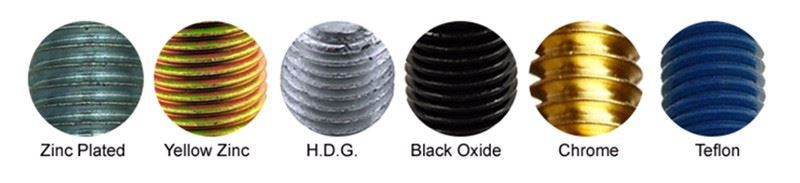

Surface technology

Product features

Round Head

Torx Drive

304 Stainless Steel

Washers Preset

FAQ

1.Q: Due to the long delivery time, how do you ensure that the product will not be damaged?

A: After our products are packed in cartons, they will be packed on pallets to ensure that the products will not be damaged during transportation.

2.Q: what is the delivery time of your products?

A: Generally speaking, the delivery time of our products is 40 days. We will customize the products according to the requirements of customers.

3.Q: How do I get after-sales service?

A: If the problem is caused by us, we will send you spare parts free of charge.

Hot Tags: sems screws, China sems screws manufacturers, suppliers, factory, m4 carriage bolt, titanium nuts and bolts, 16mm lock nut, hex screws, 14mm head bolt, bike nut bolt

You Might Also Like

Hex Socket Button Head Screws

Learn More

Double End Stud Bolt

Learn More

Stainless Steel 304 Hex Bolt

Learn More

Stainless Steel Hex Bolts

Learn More

Carbon Steel Hex Bolts

Learn More

Carbon Steel Nut

Learn More

Send Inquiry

Copyright © SIP Junly Industrial Precision Co., Ltd. All Rights Reserved.